how does flexiteek 2g become flexiteek 2G?

Read on to discover the craftsmanship and the attention to detail that goes on in the manufacturing process to make Flexiteek the high-quality market-leading product that we know and love.

To see the end results, check out our gallery to see Flexiteek on boats and yachts worldwide.

Discover the craftsmanship

ANCHOR RECEIVER

From pellet to profile

We manufacture Flexiteek decking from virgin 2G polymer pellets. Sophisticated extrusion and dosing equipment ensures extreme accuracy, which means our colours are consistent and the wood grain effect is naturally inconsistent, just like real wood.

Expert Craftsmanship

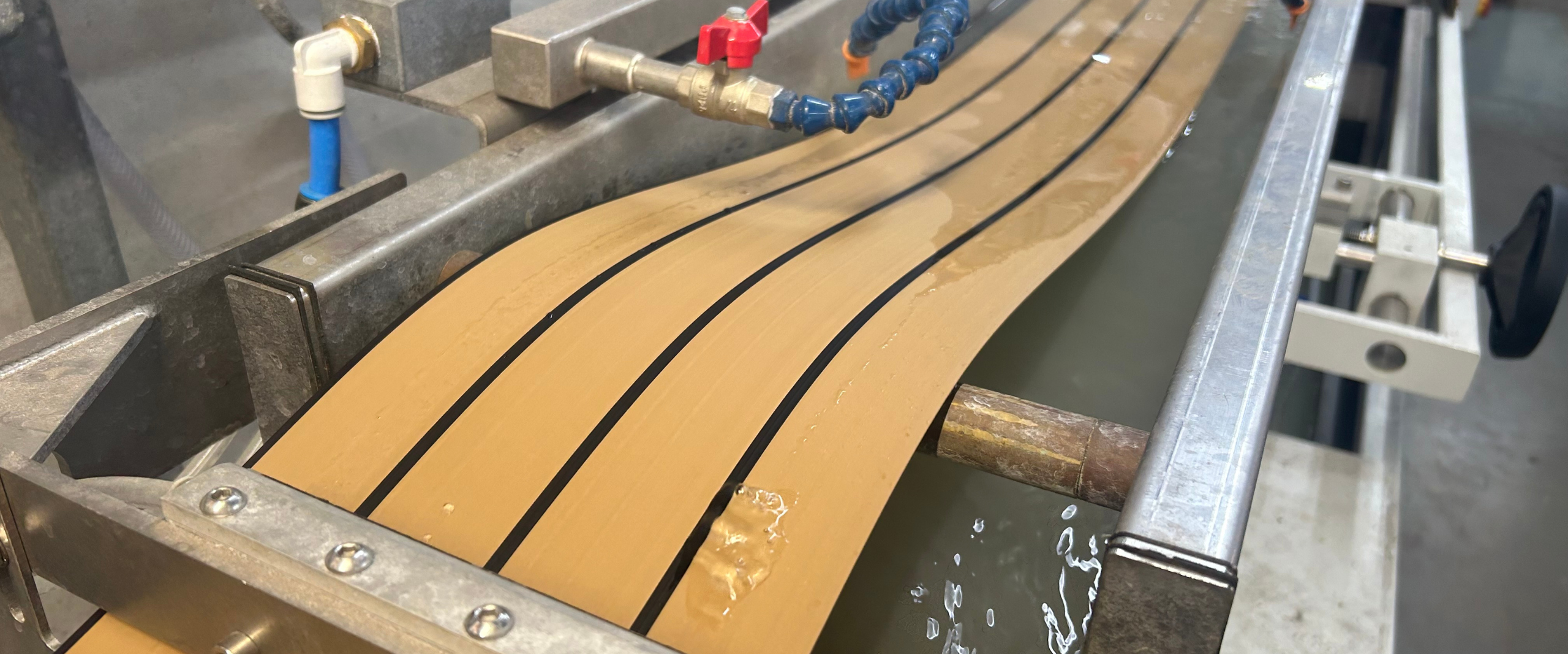

In-house designed extrusion dies control the dimensions and shape of the decking, which is cooled in a temperature-controlled water bath. Our expert craftsmen sand the surface of the decking, to bring out its grain and texture before final colour and quality checks are completed.

From profile to panel

Flexiteek panels are manufactured from profiles or planks, just like a teak deck. While a teak deck is ‘wet caulked’ to join it together, Flexiteek is vinyl welded to create a stronger joint. The caulking is either part of the extrusion, or welded into the material, ensuring a consistent finish.

Endless Design Possibilities

We can create any look you want, from traditional teak to modern designer finishes. And thanks to its flexible, surface conforming properties, anything is possible in any size.